CHAENG (Great Wall Steel Casting) offers customized processing services for companies that upgrade and replace cement ball mill spare parts.

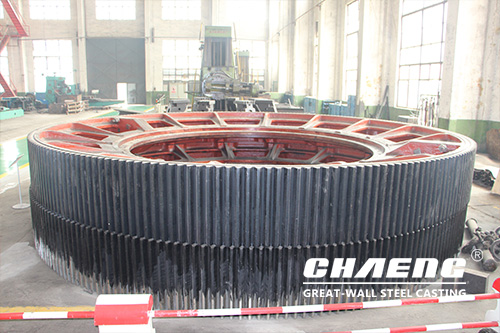

Girth gear

Diameter: 3m-12m

Process: Steel casting

Ball mill trunnion

Weight: 5-30T

Process: Steel casting

Ball mill end cover

Weight: 5-30T

Process: 5-30T

Bearing housing

Weight: 2-20T

Process: Steel casting

Process characteristics of CHAENG (Great Wall Steel Casting) cement ball mill spare parts:

1. Design the process according to customer drawings and requirements.

2. Use CAE software to simulate and optimize the casting process.

3. Strictly control the chemical composition of molten steel in the furnace, before into the furnace and after out of the furnace.

4. Advanced heat treatment technology to improve wear resistance.

Case:

CHAENG (Great Wall Steel Casting) has customized a large girth gear with a diameter of 7.3 meters and material of GS34CrMo4 for Turkish customers, which has been highly praised by customers.

The ball mills of Great Wall Machinery (CHAENG) are used in well-known cement enterprises at home and abroad such as Xinjiang Tianshan Group and Henan Mengdian Group. The matching ball mill trunnion are all produced by Great Wall Cast Steel (CHAENG).

CHAENG (Great Wall Steel Casting) wear parts are sold to Japan, and the bearing housing fully meets the requirements of the Japanese company.