The ball mill produced by CHAENG is a tubular cylinder with supporting devices at both ends. Because the grinding medium in the cylinder is steel balls, it is named ball grinding mill. The girth gear, hollow shaft, and end cover of the ball mill are all important components of the ball mill. After the ball mill runs for a long time, it is necessary to maintain and replace the spare parts in time, which can effectively prolong the service life of the equipment.

Girth gear is an important transmission part. CHAENG girth gear is widely demanded in different industries to be installed in different machines, such as rotary kilns, rotary dryers, and ball mills. It is available in different specifications according to the requirements of the customers.

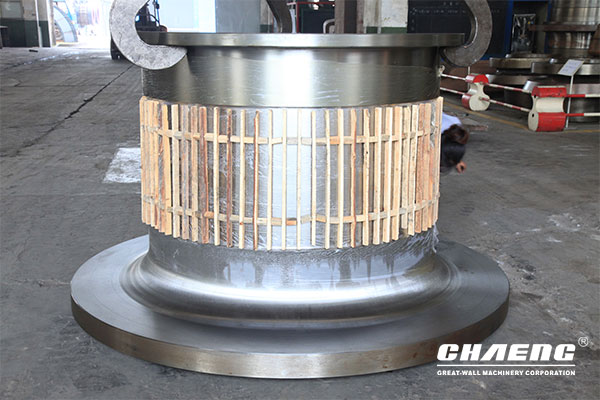

The ball mill trunnion, also called the ball mill hollow shaft, is a key part to support and connect the cylinder and is also the inlet and outlet channel of the material. CHAENG adopts high-strength steel and unique heat treatment technology, which makes ball mill trunnion have high hardness and strong impact resistance.

The ball mill head, also called the ball mill end cover, is one of the key components of the ball mill, located at both ends of the ball mill shell and is mainly used to support the material, the cylinder, and the grinding media.