Professional teams & Customized solution

Before production, according to the customer's drawings and requirements, CHAENG fully communicates with the customer to develop a specific production plan for the slag pot; During production, the process is strictly controlled from molding, pouring, finishing to testing, to ensure the quality of the slag pots.

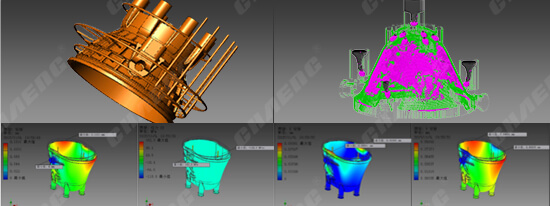

Analyzing & Simulating

CHAENG uses CAE software to digitally simulate the casting process of slag pots, directly observes its filling and solidification process, and directly predicts with graphs and data the location and size of various casting defects that may be generated, thereby optimizing the adjustment process to develop the best process plan.

Heat treatment process

CHAENG owns natural gas CNC heat treatment furnaces of 7m*12m and 5m*7m for heat treatment process to eliminate casting defects such as porosity, cracks, shrinkage, uneven structure, residual internal stress and so on, to improve the mechanical properties of slag pots.

Strict quality inspection

CHAENG has a complete slag pot inspection system to strictly test the whole slag pot, especially the bottom, trunnion and tilting mechanism, and CHAENG also can customize the test process according to customer's specific standards. CHAENG's main flaw detection technologies:UT, MT, PT, X-ray, etc.

Slag pot is the main product of CHAENG, more than 95% of CHAENG slag pots and ladles are exported abroad, such as the United States, Canada, Mexico, Brazil, Germany, Turkey, India, Korea, Japan.

Slag pot is important device in steel making. It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes.

CHAENG has the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as "high cost-effective steel castings manufacturer".

CHAENG has strong technical teams, detailed production scheduling, wide range of raw materials purchase channels, and perfect logistics delivery system, making efforts to achieve as fast delivery period as required.

The 24h fast response and the customer services in all 365 days rest your heart when you make choice, ease your heart when you use the products, satisfy your heart when you enjoy the services.